You must choose the right liquid filling machine for your production line to meet your goals. Matching the machine to your product’s thickness, container, and how much you need helps you work better. Thin liquids fill fast with gravity machines, while thick products require piston or pump fillers to keep things moving. If you use a gravity filler for thick liquids, your process may slow down. You should evaluate what you need now and consider future changes to stay efficient.

Know how thick your product is. Pick a filling machine that works with your liquid’s thickness. This helps stop spills and slow work.

Think about how much you need to fill each day. Choose a machine that can handle your daily work. This keeps your business running well.

Look at how much the machine does by itself. Automated machines can save time. They also help you spend less on workers. This can help your business get bigger.

Make sure the machine works with your bottles. The right machine should fit your bottle’s size and shape. This helps fill bottles the right way.

Think about how your business might grow. Pick a machine you can upgrade later. This helps you add new features as you need them.

When you pick the right liquid filling machine, start with viscosity. Viscosity tells you if your liquid is thick or thin. Water is thin and moves fast. Honey is thick and moves slow. You need a machine that matches how your product flows. Using the wrong machine can cause spills or slow work.

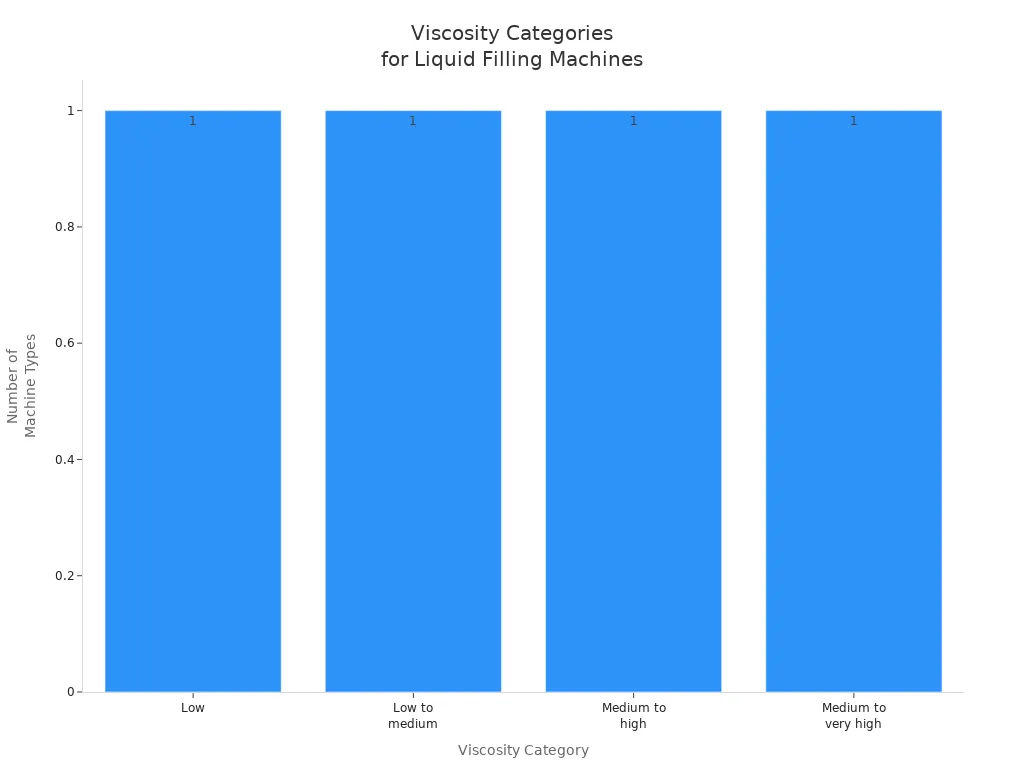

Here is a table that shows which machines work best for different viscosities:

Filling Machine Type | Best For | Viscosity Range |

|---|---|---|

Gravity Fillers | Water, juice, cleaners | Low |

Overflow Fillers | Foamy products (soaps) | Low to medium |

Pump Fillers | Oils, syrups, gels | Medium to high |

Piston Fillers | Lotions, creams, sauces | Medium to very high |

Viscosity changes how you fill bottles. Thin liquids like water use gravity fillers. These machines let gravity move liquid into bottles fast. Medium liquids, like oils or syrups, need pump or piston fillers. These machines push liquid with more force. Thick products, like creams or sauces, need piston fillers or servo-driven fillers. These machines use pressure and special nozzles to fill thick liquids well.

If you want to see how many machine types fit each viscosity, look at this chart:

Tip: Always test your product with the machine before you buy it. This helps you avoid mistakes and keeps your line working well.

Think about how much product you want to fill each day. Production volume means how many bottles you need to fill. Speed is how fast your machine can fill them. If you choose the right liquid filling machine, you can reach your daily goals and avoid being late.

Here is a table that shows recommended machine capacities for different production scales:

Scale | Capacity (units per hour) |

|---|---|

Small-scale | 500 to 5,000 |

Medium-scale | 5,000 to 20,000 |

Large-scale | 20,000 to 100,000 |

Small businesses may only need a machine for 500 bottles per hour. Medium companies often need up to 20,000 bottles per hour. Big factories need machines that fill up to 100,000 bottles per hour.

The speed you need decides which machine is best.

Fast machines help you meet big orders.

Faster machines may need more setup and care.

Machines with many filling heads and automatic systems are best for fast work.

These advanced machines cost more, but they save time and make more products.

Note: If you want your business to grow, pick a machine that can fill more bottles later.

Automation means how much the machine works by itself. Some machines need people to run them. Others work on their own with little help. When you choose the right liquid filling machine, think about labor costs and how fast you want to work.

Automated machines can save you money and time. In big factories, automation can cut labor costs by almost half. A study found that automated lines lower labor costs by one-third and make more products. If you use fully automated machines, you may see labor costs drop by about 40%. This helps you get your money back faster.

Here is a table that shows how automation helps your production:

Benefit | Description |

|---|---|

Increased Efficiency | Automated systems work faster than people. |

Reduced Downtime | Automation means fewer mistakes and less stopping. |

Improved Accuracy | Automatic machines fill bottles with the same amount every time. |

Scaled Profitability | More efficiency and less waste mean more profit. |

Automated machines run with little stopping, so you make more products.

They fill bottles with the right amount, so there is less waste.

Automated systems work with many liquids and bottles, so you can use them for different products.

Tip: If you want to save money and work faster, get a machine with more automation. This helps your business grow and keeps your line strong.

When you choose the right liquid filling machine, always think about viscosity, how much you need to fill, and how much automation you want. These steps help you pick the best machine for your line now and later.

There are a few main types of liquid filling machines. Each one works best for certain products.

Gravity Fillers let gravity move liquid into bottles. Use these for thin liquids like water or juice. Gravity fillers are easy to use and cheap. They can be slow and do not work well with thick or foamy liquids.

Piston Fillers use a piston to push liquid into bottles. These machines fill bottles fast and very accurately. Use piston fillers for thick products like creams or sauces. They work for small and big batches. Piston fillers are harder to use and need trained workers.

Pump Fillers use pumps to move liquid. You can use them for thin or thick liquids. Pump fillers are flexible but may not be as exact as piston fillers.

Overflow Fillers fill bottles until liquid spills out. This makes every bottle look the same. Use overflow fillers when you need the fill level to match, like in clear bottles. They work best for thin or foamy liquids like soaps.

Here is a table to help you compare the main types:

Machine Type | Best For | Main Advantage | Limitation |

|---|---|---|---|

Gravity | Water, juice, cleaners | Simple, low cost | Slow, not for thick liquids |

Piston | Creams, sauces, lotions | Fast, precise | Complex, needs skill |

Pump | Oils, gels, syrups | Versatile | Less accurate |

Overflow | Soaps, foamy products | Uniform fill level | Not for thick products |

Tip: Always pick the machine that matches your product’s thickness and flow. This helps you get the best results.

When you choose the right liquid filling machine, think about what makes your product special. Thin liquids like water work best with gravity fillers. Thick or sticky products, like honey or cream, need piston or pump fillers for smooth filling. If your product is foamy or you want bottles to look the same, overflow fillers are a good choice.

You should also think about if your product has bubbles, is thick, or has pieces in it. For fizzy drinks, pressure filling or special nozzles keep bubbles inside. For thick products, vacuum or special pumps stop air pockets and help fill evenly.

Product thickness

Bottle shape and size

How fast and accurate you need to fill

How much the machine does by itself

Note: The right machine helps you stop spills, waste less, and keep your line working well.

If you want to choose the right liquid filling machine, always match what the machine does best to what your product needs. This helps you get good results and quality for your production line.

You must pick a liquid filling machine that fits your bottles. The size and shape of bottles change how the machine works. Big bottles need large nozzles to fill them fast and right. Small bottles can spill if filled too quickly. The bottle opening size is important. If the nozzle is too big or small, you might get leaks or slow filling. Gravity and overflow filling machines have different nozzle shapes. These help you fill bottles to the same level each time.

When picking a machine, think about these things:

The size and shape of your container decide which machine you need.

Small vials need a different machine than big bottles.

How fast you fill bottles tells you how much automation you need.

The thickness of your liquid changes which machine works best.

You may need to change your machine for different bottles or products.

Some common problems with packaging are:

Dust or dirt can get in and spoil your product.

Liquids can leak if bottles do not close well.

Fill levels can be uneven and hurt your product quality.

Air can get trapped and make bubbles in bottles.

Thick liquids can clog the machine.

Bottles can spill if they are not steady during filling.

Tip: Always test your bottles with the machine before you start. This helps stop spills and keeps your line working well.

Sometimes you need to use new bottles or products. Fast changeover saves time and money. The best machines let you change settings quickly without tools. You can use hand knobs or cranks to move bottle guides and nozzles. Some machines have screens to save fill settings for each product. You can switch between products fast and easy.

Clean-In-Place (CIP) systems help you clean the machine quickly. You do not have to take the machine apart. This saves time and keeps your line running well.

Best Practice | Description |

|---|---|

Tool-less Changeover | Use hand knobs or cranks to adjust bottle guides and nozzles. |

Recipe Management | Save and use fill settings on a screen. |

Clean-In-Place (CIP) | Clean the machine fast without taking it apart. |

Note: Flexible machines help your business grow. You can fill many kinds of bottles and products without waiting a long time.

You must keep your liquid filling machine clean. This stops germs from getting in your product. If you do not clean the machine, your line may stop. Every minute the machine is off, you make less product. Downtime means your machine is not working as it should. This can happen when you clean, fix, or if it breaks down.

Planned downtime is when you know the machine will stop. You can plan for this and lose less work.

Unplanned downtime happens without warning. It can stop your whole line fast.

Every hour your machine stops without warning can cost a lot of money.

Pick machines that are easy to clean and have quick-change parts. Clean-In-Place (CIP) systems help you clean faster. This means less time with the machine off. The right liquid filling machine keeps your line working and saves money.

It is important to fill each bottle with the right amount. This helps you waste less and keeps customers happy. If every bottle is filled the same, you follow the rules and build trust. Accurate filling also saves you money by using less product.

Manufacturers use different ways to make sure filling is right:

Automated systems help stop mistakes made by people.

Operators can change settings fast on HMI screens.

Centralized monitoring lets you check quality everywhere.

Check your machine’s calibration often to keep it accurate. Clean nozzles and tight seals stop leaks and underfills. Real-time inspection systems find problems fast so you can fix them. Some machines can fill bottles almost perfectly, which is great for quality.

You need a good company when you buy a liquid filling machine. Pick a manufacturer with lots of experience and a good name. Look at their past work and ask for stories or references. Good customer service is important for fixing and caring for your machine.

The company should have a good record in the industry.

They should help you when you need it.

They must offer maintenance and spare parts.

Ask for positive stories from other customers.

A trusted manufacturer helps your line run well and supports your business as it grows.

When you choose a liquid filling machine, you need to balance cost and value. Prices can vary a lot based on the type and features of the machine. Here is a table that shows typical price ranges and how many bottles each machine can fill per hour:

Machine Type | Price Range | Typical Throughput |

|---|---|---|

Manual | $1,000‒$5,000 | 20‒50 bottles/hour |

Semi-Automatic | $5,000‒$20,000 | 50‒200 bottles/hour |

Automatic | $20,000‒$100,000+ | 200‒3,000+ bottles/hour |

Most businesses spend between $5,000 and $50,000 for a machine that fits their needs. You may pay more at first, but you save money over time. Automated machines help you work faster, use less labor, and waste less product. These savings add up and help you get your money back.

Tip: Look at more than just the price. Think about how much you will save on labor and waste. A higher-priced machine can give you better value if it helps you work smarter.

You should also consider these factors when you decide on value:

Automation Level: More automation means less manual work.

Production Volume: Higher volume needs a faster machine.

Product Type: Some machines work better with certain liquids.

Your business may grow, so you need a machine that can grow with you. Many machines let you add more fill heads or upgrade controls. This means you do not have to buy a new machine when you need to make more products.

Upgrade Type | Description |

|---|---|

Additional Fill Heads | Add more fill heads to increase how many bottles you fill. |

Design for Future Upgrades | Machines often have space and controls ready for more features. |

Economic Benefits | Upgrading costs less than buying a new machine. |

You can start with a tabletop or semi-automatic filler. These machines let you add more fill heads as your needs grow. Some machines also offer real-time monitoring and predictive maintenance. These features help you spot problems early and keep your line running.

Note: Choose a machine that supports upgrades. This helps you save money and makes it easy to meet new production goals.

You can choose the right liquid filling machine by following a few key steps:

Learn about different machine types and their features.

Check your production volume and speed needs.

Look for machines with easy maintenance and advanced controls.

Make sure the machine matches your product and container.

Request a demonstration to see how the machine works with your product. Research suppliers to find strong support and reliability. Create a checklist of your needs before you contact suppliers for quotes. This helps you pick a machine that fits your goals and grows with your business.

You should use a piston filler for thick products like creams or sauces. Piston fillers push thick liquids into bottles with strong force. This helps you fill each bottle quickly and accurately.

Check the machine’s specifications. Many machines have adjustable guides and nozzles. You can fill small and large bottles by changing these settings. Some machines also save recipes for each bottle size.

You should clean your machine every day after use. Regular cleaning stops germs and keeps your product safe. Machines with Clean-In-Place (CIP) systems make cleaning faster and easier.

Yes! Many machines let you add more fill heads or upgrade controls. You can start small and expand later. This saves money and helps you meet new production goals.