You want to fill bottles fast and with care. A gallon filling machine works faster than doing it by hand. Machines fill bottles quickly and give the same results each time. Filling bottles by hand takes longer and is harder. There are different machines for different jobs.

Type of Machine | Description | Applications |

|---|---|---|

Fully Automatic Gallon Filling Machine | Works alone, good for big jobs. | High volume production |

Semi-Automatic Gallon Filling Machine | Needs some help from people, good for smaller jobs. | Small to medium scale |

Weight Gallon Filling Machine | Stops at a set weight to fill bottles right. | Heavy-weight containers |

Gravity Gallon Filling Machine | Uses gravity to fill, easy and flexible. | Many gallon sizes |

Think about how getting the right machine can help you work better and faster.

Gallon filling machines help you fill bottles fast. They let businesses finish more orders in less time. Automation makes sure each bottle gets the same amount. This cuts down on waste and saves money on workers. It also helps make better products. There are different machines for different jobs. You can pick a fully automatic machine for lots of bottles. Or you can use a semi-automatic one for fewer bottles. The controls are simple to use. Anyone can learn to use the machine quickly. This means fewer mistakes and less training. You need to clean and check the machine often. This helps it work well and last longer.

A gallon filling machine lets you fill bottles fast and right. You put empty bottles on the machine. The machine uses special systems to pour liquid in each bottle. Some machines have a dual nozzle system. This system lets you change how fast you fill each product. It also stops foam by keeping the nozzle close to the liquid. The nozzle helps stop drips, so fills are more exact.

The dual nozzle system:

Lets you pick how fast to fill each product.

Stops foam by keeping the nozzle near the liquid.

Stops drips for better fills.

There are two main ways the machine moves liquid. Gravity feed and gear pumps are used.

Gravity feed is best for thin liquids like water. The liquid falls into the bottle using gravity.

Gear pumps are good for thick liquids. These pumps move liquid at the same speed, so each bottle gets the same amount.

Tip: Use gravity feed for water or juice. Use gear pumps for oils or syrups.

You can use a gallon filling machine with many bottle types. Machines work with PET, HDPE, and glass bottles. Each type has its own good points.

Container Type | Compatibility Considerations |

|---|---|

PET | Works well for drinks and other products. |

HDPE | Best for chemicals, soaps, and drinks without bubbles. Handles strong liquids. |

Glass | Keeps things clean and fresh. Strong and hard to scratch. |

Automation makes your work easier. A gallon filling machine with automation fills bottles with the same amount each time. You do not need to watch every step. The machine does most of the work for you.

Automation gives you:

Exact fills for every bottle.

Fewer mistakes because the machine controls the steps.

Lower costs since you need less help from people.

Faster work because the machine does not stop.

You can set the machine to fill different bottle sizes and types. You save time and fill more bottles quickly. Automation helps you keep your products the same and your business working well.

You can adjust many settings on a gallon filling machine to match your needs. These settings help you fill different bottle sizes and volumes with ease. You can change the fill volume, fill rate, and even save your favorite settings for later use. Some machines let you adjust the shelf height or use a digital timer for more control.

Feature | Description |

|---|---|

Fill Volume | Adjustable from 1 oz to over 1 gallon |

Fill Rate | Up to 120 containers per minute |

Cleaning | Simple process, no tools required |

Control | 7" Touch screen controls |

Memory | Save up to 99 recipes |

Shelf | Adjustable for various bottle sizes |

Timer Control | Digital timer adjustable down to .01 seconds |

Tip: You can quickly switch between different bottle sizes and recipes. This saves you time and keeps your production running smoothly.

You want to fill as many bottles as possible in a short time. Machines with more filling heads, like the Eight-Head Poly Filler or the 24 Head Gravity Feed, let you fill many bottles at once. The XPG-200 is another example that offers high speed and accuracy. When you use a machine with more heads, you increase your production and reduce waiting time.

More filling heads mean:

Faster filling for large orders.

Less time spent on each batch.

Better use of your staff and equipment.

A gallon filling machine with 24 heads can fill 24 bottles at the same time. This boosts your output and helps you meet big orders without delay. Machines with advanced automation also keep each fill accurate and reduce product loss.

Easy-to-use controls help you work faster and make fewer mistakes. Many machines have touch screens and simple buttons. You can learn how to use these controls quickly, even if you are new to the job. User-friendly controls also help you avoid errors and keep your workflow smooth.

Note: Simple controls mean less training time for your team. You can start filling bottles right away and keep your process efficient.

You should also keep your machine in good shape. Regular cleaning, checking parts, and updating software help your machine last longer and work better. Always train your team on how to use and care for the machine.

You want to fill bottles fast and keep your business busy. Filling bottles by hand takes a long time. You have to fill each bottle one at a time. This slows down your work. A gallon filling machine fills many bottles together. The machine works quickly and never gets tired. You can fill hundreds of bottles while hand filling only a few.

Using an automated filling machine saves you money too. You need fewer people to run the machine. Labor costs can go down by half. Your team can do other important tasks. This helps your business grow and keeps things running well.

Here is a simple table showing how machines help businesses that fill lots of bottles:

Benefit | Explanation |

|---|---|

Improved production efficiency | Machines fill bottles faster, so you handle more orders in less time. |

Reduced labor costs | Fewer workers needed, saving money on wages. |

Financial savings | Less waste and fewer mistakes mean you save money in the long run. |

Tip: If you fill lots of bottles every day, a machine helps you finish much faster.

You want every bottle to look the same and have the right amount inside. Hand filling depends on how careful each worker is. Some bottles might have too much or too little. This can make customers unhappy and waste product.

A gallon filling machine uses sensors and controls. Each bottle gets the same amount every time. This keeps your product quality high and cuts down on waste. Machines also help the environment by stopping spills and using bottles again.

Criteria | Automated Machines | Manual Machines |

|---|---|---|

Accuracy | Very high | Variable |

Waste Generation | Low | High |

Water Wastage | Low | High |

Automated machines use sensors for even fills, so you waste less.

Manual filling can lead to mistakes and more waste.

Machines let you use reusable bottles, which helps the planet.

Note: Consistent fills keep your customers happy and help your business stand out.

You want your business to get bigger and do more work. A gallon filling machine helps you fill bottles faster. This makes your production line work better. With a machine, you can fill many bottles in less time. You can take on more jobs and keep up with what customers want.

Improvement Type | Description |

|---|---|

Increased Production Speed | Filling machines fill bottles quickly, so you make more each day. |

Reduced Wastage | Machines fill bottles with the right amount, so you lose less product. |

Enhanced Accuracy | New technology helps machines fill bottles the same way every time. |

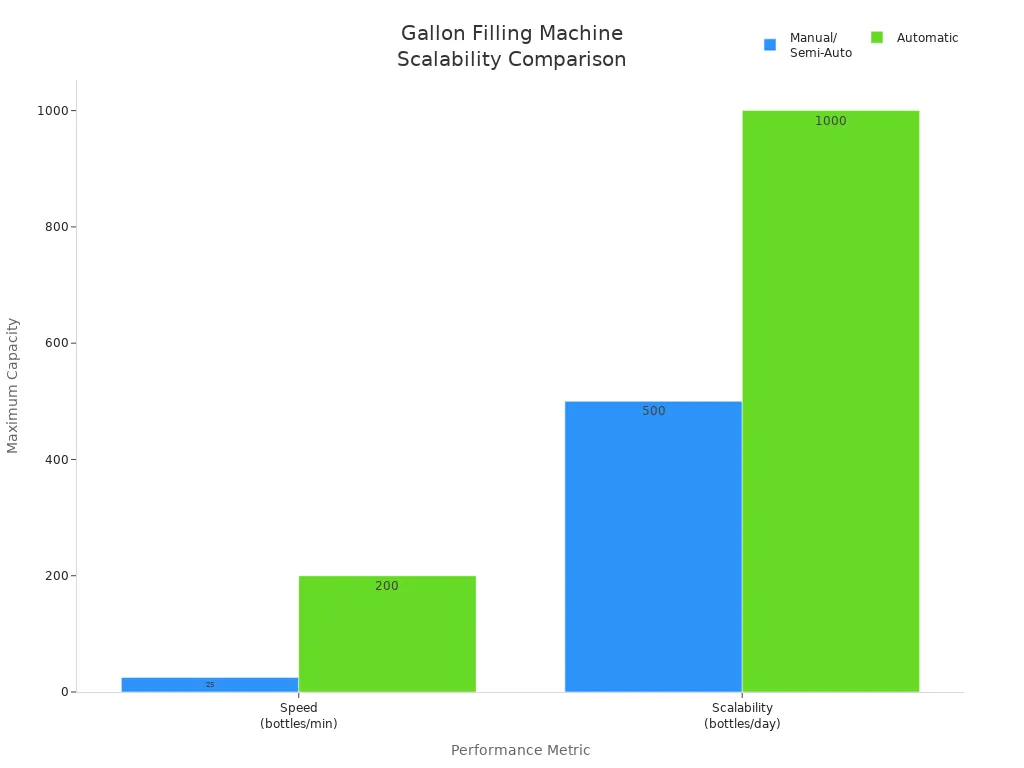

Automatic machines help you fill more bottles. They can fill up to 200 bottles in one minute. If you fill by hand, you only do about 25 bottles in a minute. This fast speed helps your business grow when you get more orders.

Tip: Automated machines fill more bottles in less time. You finish jobs faster and can do more work.

You save money because you need fewer workers to fill bottles. A gallon filling machine does most of the job for you. One or two people can run the machine, even for big batches. You spend less on paying workers and can use your team for other jobs.

Evidence Description | Labor Savings Achieved |

|---|---|

Fully automatic machines mean you need fewer people. | You save a lot of money on workers. |

The machine’s small size and smart design save money on materials. | You spend less to buy and run the machine. |

The machine works all the time without stopping a lot. | You make more bottles and waste less time. |

Note: Using machines helps you spend less on workers, which is good if labor costs go up.

You want every bottle to have the same amount inside. This keeps your customers happy and helps you follow the rules. A gallon filling machine uses sensors and automation to fill each bottle just right.

Feature | Description |

|---|---|

Automation | The machine fills, puts on lids, and moves bottles by itself. |

Fill Accuracy | The machine fills bottles with the right amount every time. |

You make fewer mistakes and waste less product. Your bottles look neat and pass quality checks every time.

Consistent fills help your customers trust you and make your brand stronger.

When you choose a gallon filling machine, you need to look at several important factors. Start by thinking about the type of product you want to fill. Some liquids, like syrups or oils, are thick and need special equipment. Others, like water, need machines that can handle foam and keep things clean. You also need to check the cleanliness requirements. Food and drink products often need machines that meet strict hygiene standards.

You should look at the types and shapes of containers you plan to use. Some machines work with many sizes, from 1 gallon to 5 gallons. Make sure the machine fits your bottles, whether they are PET, HDPE, or glass. Think about how fast you want to fill bottles. If you need to fill many bottles each day, you may want a machine with a high fill rate and more automation.

Other things to consider include:

Available floor space in your facility

Your budget for the machine and future support

The level of automation you want

The need for testing and after-sales support

Tip: Measure your space before you buy. Make sure the machine will fit and leave room for workers to move safely.

You need to match the machine to your business needs. If you run a small shop, a semi-automatic machine may work best. These machines cost less and are easier to use. You will need someone to run the machine, but you save money at the start. For bigger businesses, a fully automatic machine fills bottles faster and needs less help from workers. These machines cost more but save money over time.

Feature | Semi-Automatic Machines | Fully Automatic Machines |

|---|---|---|

Operator Requirement | Needs an operator to start each fill | Runs on its own after setup |

Labor Costs | Higher, more workers needed | Lower, fewer workers needed |

Initial Cost | Lower, starts around $20,000 | Higher, starts around $30,000 |

Output Speed | Slower, depends on operator | Faster, good for big jobs |

If you fill bottled water, you need a machine that keeps everything clean and safe. For edible oils, you may need a machine that handles thick liquids and meets food safety rules. Always check if the machine can grow with your business. Some machines let you add more features later.

Note: Think about your future needs. A machine that works for you now should also help you grow.

A gallon filling machine lets you fill bottles fast. It helps you keep your work the same every time. You get good accuracy and quick speeds. The controls are simple to use. You can fill more bottles in less time. This helps you save money because you waste less.

Type of Filling Machine | Speed | Productivity | Ease of Use |

|---|---|---|---|

Automatic Fillers | High | High | Low (no operator) |

Semi-Automatic Fillers | Moderate | Moderate | Moderate |

Manual Filling Machines | Low | Low | High (manual) |

You should think about what you need for your work. Look at your costs and how much automation you want before picking a machine.

You can clean most machines by running water or cleaning solution through the system. Some models have a cleaning mode. Always follow the manual for best results. Regular cleaning keeps your machine safe and working well.

Yes, you can. Many machines let you adjust the shelf and fill settings. You can switch between bottle sizes quickly. This helps you save time and fill many types of bottles.

You can fill water, juice, oil, syrup, and even some chemicals. Check the machine’s specs before use. Some machines work better with thick liquids. Others handle thin or foamy liquids best.

You should check parts, clean the machine, and update software often. Most machines need only simple care. Good maintenance helps your machine last longer and work better.